Vacuum Tanks

Vacuum Tanks

Perfect Vacuum, Perfect Solution

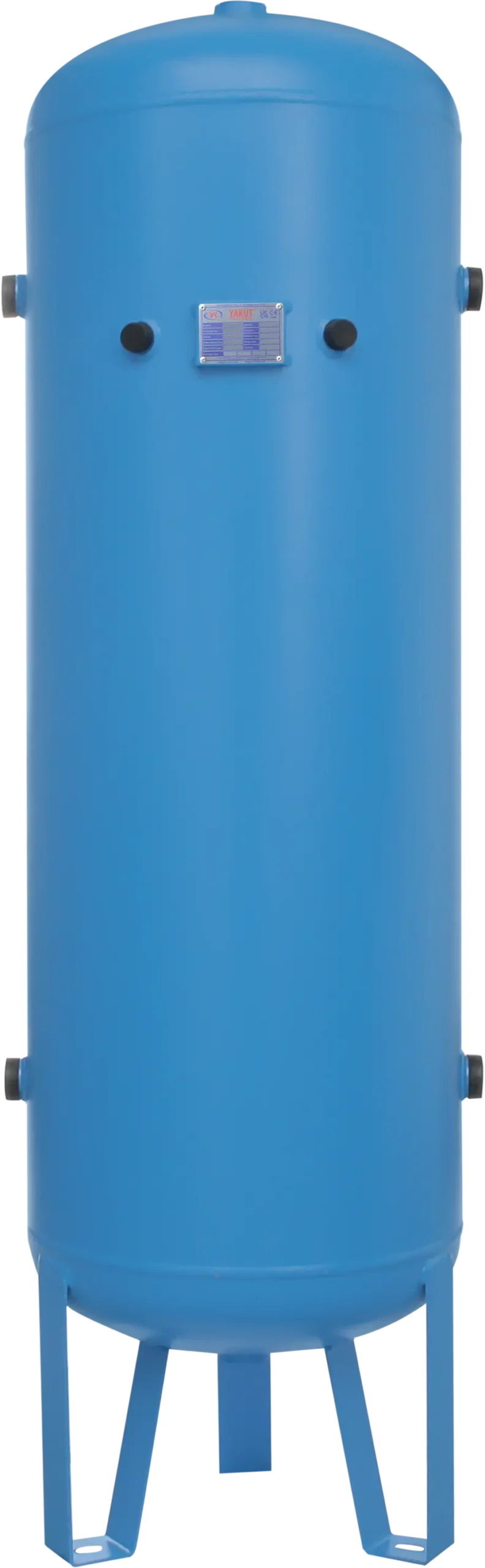

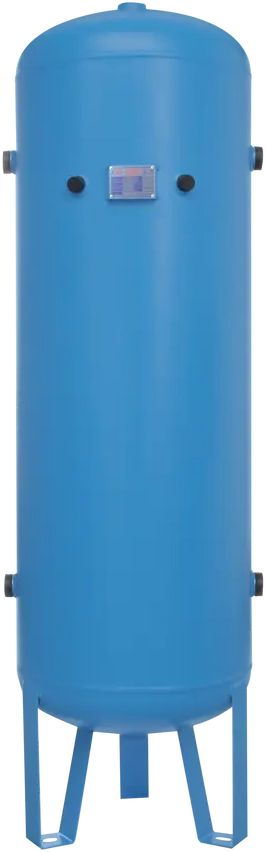

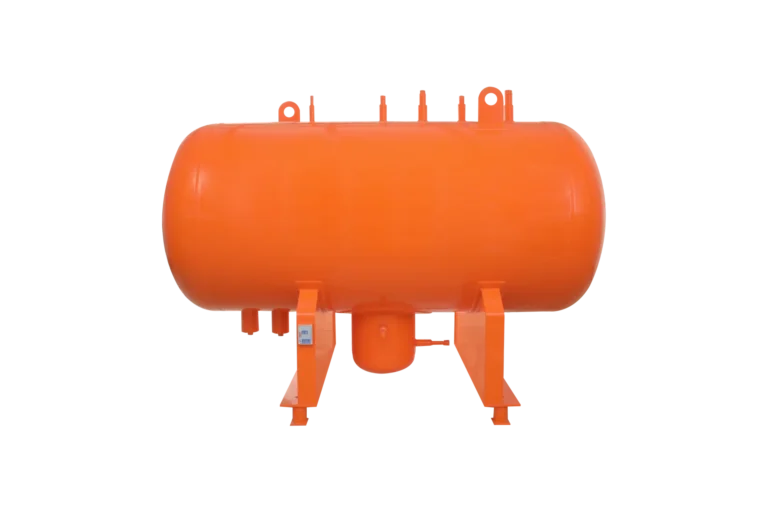

Vacuum technologies are used in a wide range of industries, from electronics production to the food industry, from chemical production to automotive. Vacuum tanks are one of the basic components of these technologies. As Yakut Kazan, we offer reliable and efficient solutions to our customers with vacuum tanks that we produce at high quality standards.

High quality vacuum tanks are of great importance for the safe, effective and long-lasting storage and use of vacuum. Yakut Kazan leads the sector with vacuum tanks produced at world standards to meet this need. Our tanks made of high quality materials are corrosion resistant, long lasting and hygienic. Designed with advanced engineering calculations, our tanks provide a perfect vacuum environment for all kinds of industrial applications.

Yakut Kazan compressed air tanks are manufactured in accordance with internationally recognized quality standards such as ASME, DIN, CE, TÜV, BREAU VERITAS, RINA, DNV GL, EAC, CLASSNK, ABS, CCS, LIOYD'S REGISTER, TÜRK LOYDU, RINA, RUSSIAN MARITIME REGISTER SHIPPING, TÜV CERT, TÜV SÜD, GOST, TÜV AUSTRIA. The safety and durability of the products are ensured at the highest level.

- Creating a Vacuum Environment: The primary function of vacuum tanks is to create a vacuum environment by removing air or other gases from inside. This means that the pressure is reduced below atmospheric pressure.

- Liquid or Gas Storage: Vacuum tanks can be used to store a variety of liquids or gases. The vacuum environment helps maintain the stability and purity of these substances.

- Process Control: Vacuum tanks can be used to control pressure and flow in industrial processes. This is important for precision manufacturing and processing.

Yakut Kazan constantly renews itself and offers its customers reliable and efficient air tanks with the latest technology.

Sustainable Production

Quality Material

Fast Delivery

Certified Product

Advantages of Ruby Boiler Vacuum Tanks

- Long-lasting: Provides trouble-free use for many years thanks to high-quality materials.

- Reliable: Its reliability has been proven thanks to production in accordance with international standards.

- Efficient: Speeds up operations and saves energy.

- Customizable: Special designs can be made according to customer needs.

Features of Yakut Boiler Vacuum Tanks

-

- High Quality Material: Many parameters such as chemical composition, mechanical properties and surface quality of the materials are controlled.

- Excellent Vacuum Performance: Our vacuum tanks designed with advanced engineering calculations easily provide the desired vacuum level.

- High Vacuum Levels: The tanks we produce have the ability to reach high vacuum levels.

- Pressure Tests: All vacuum tanks produced are subjected to meticulous pressure tests for safe use.

- Electrostatic Powder Paint: It is coated with electrostatic powder paint that provides additional protection against corrosion.

- Hygienic Design: Our vacuum tanks used in the food and pharmaceutical sectors are easy to clean thanks to their hygienic surfaces.

Definitive Solution in Vacuum with Yakut Boiler Assurance

- Yakut Kazan aims to provide the best service to its customers with its expert staff and modern production facilities on vacuum tanks. If you also need a vacuum tank, you can find the most suitable solution for your project by consulting Yakut Kazan’s expert staff.

Certificates

Quality & Flawless

Industrial Solutions

Yakut Kazan is a pioneer in the sector with its specially designed and high quality tank manufacturing that adds value to the production processes of its customers.

PRODUCTS

The Choice of Successful Engineers Around the World Yakut Kazan

Our products are exported to GERMANY, ARNAVATIA, AUSTRALIA, AZERBAIJAN, UAE, BELGIUM, BOSNA HERSEK, BULGARIA, CZAY, CZECH, DENMARK, DOMINIC REPUBLIC, Ecuador, FAS, FRANCE, GABON, GANA, SOUTH AFRICA, GEORGIA, CROATIA, NETHERLANDS, IRAQ, UK, IRELAND, The products are exported to SPAIN, SWEDEN, ITALY, CANADA, QATAR, KENYA, KOREA, KOSOVA, LETONIA, HUNGARY, MACEDONIA, EGYPT, MOLDOVA, NEPAL, NORWAY, PERU, PORTUGAL, ROMANIA, SERBIA, SLOVAKIA, SLOVENIA, SAUDI ARABIA, TANZANIA, OMAN, GREECE.