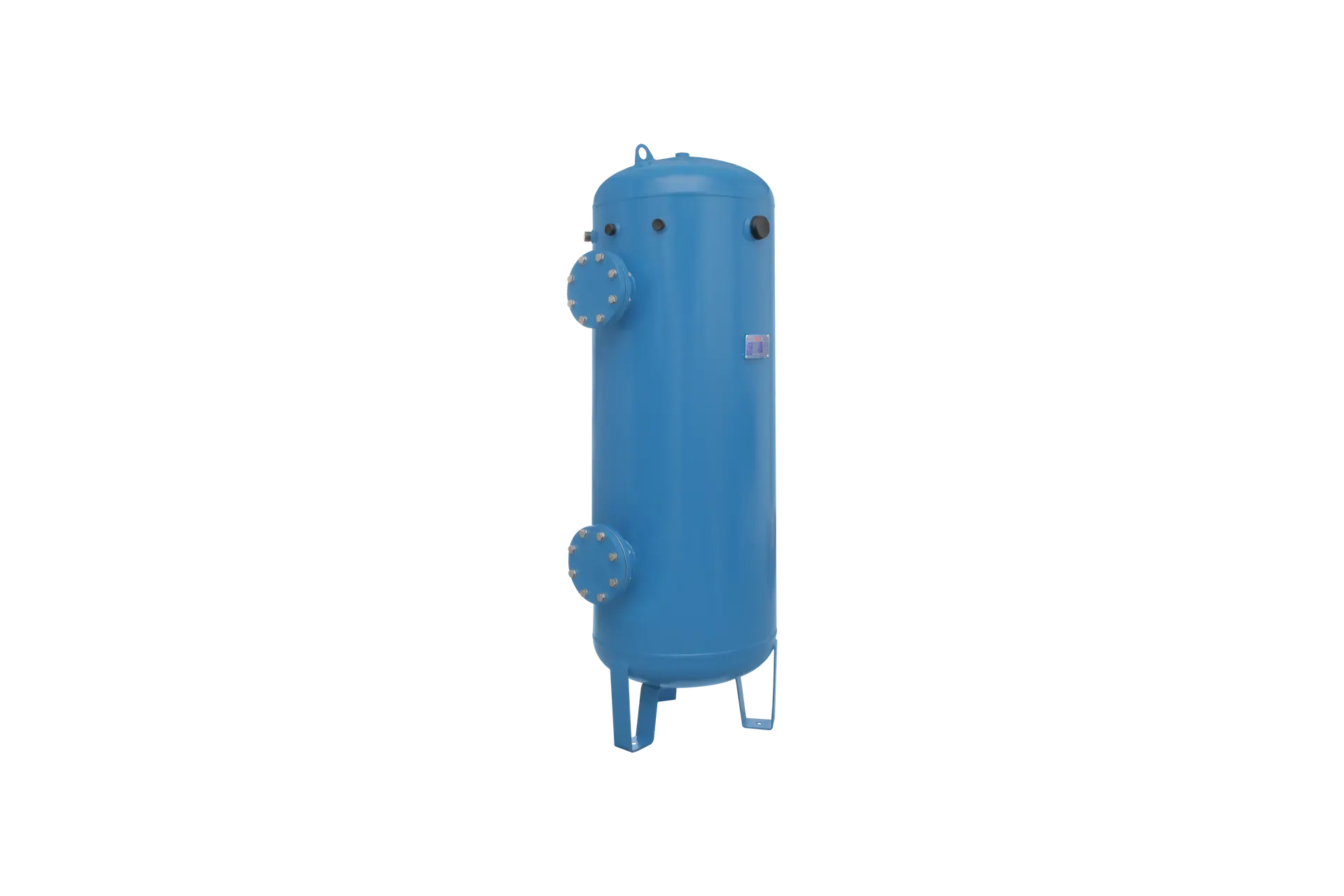

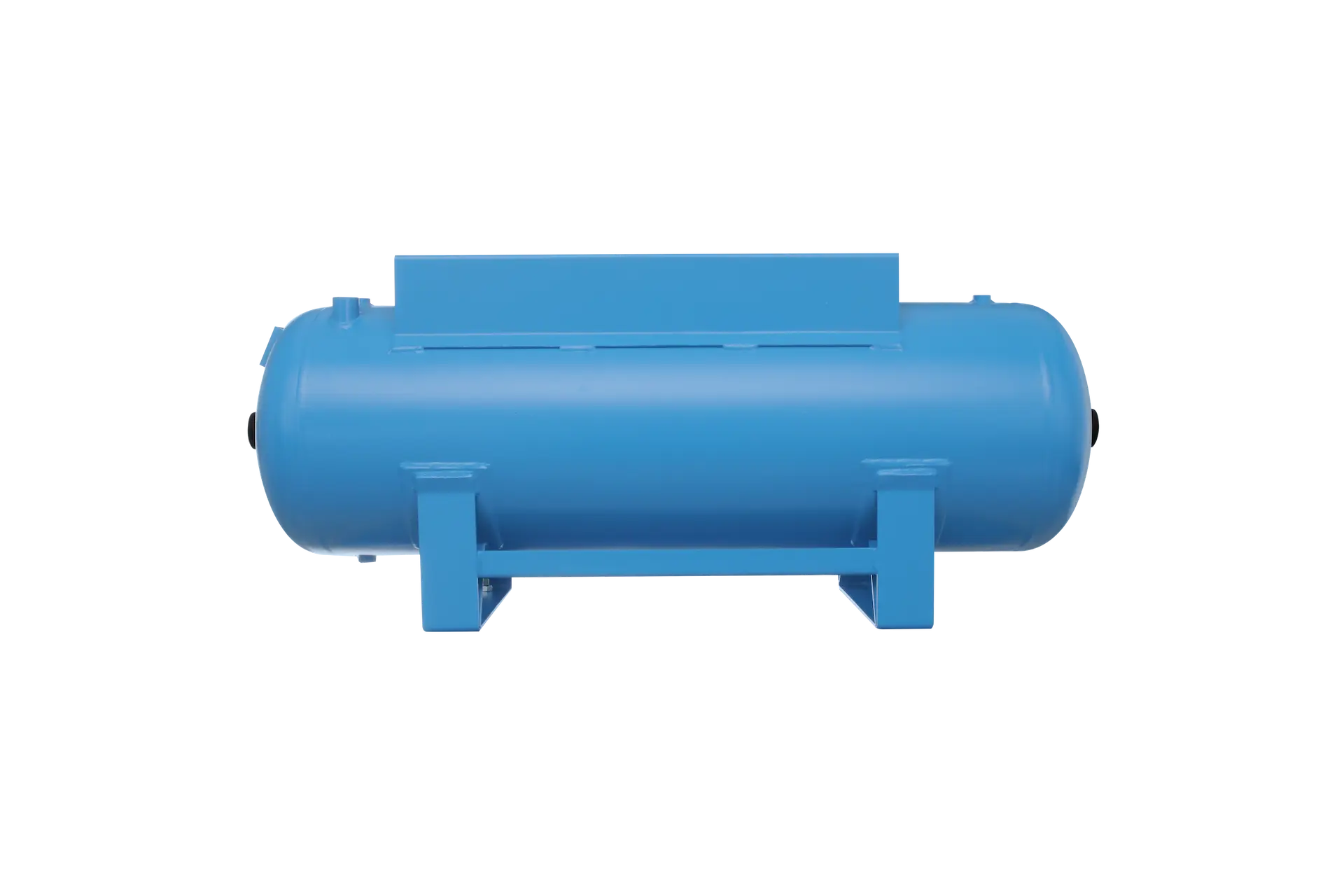

Compressor Air Tank

Compressor Air Tank

Perfect Solutions in Compressed Air Compressor Tank Production

Yakut Kazan compressed air tanks are manufactured in accordance with internationally recognized quality standards such as ASME, DIN, CE, TÜV, BREAU VERITAS, RINA, DNV GL, EAC, CLASSNK, ABS, CCS, LIOYD'S REGISTER, TÜRK LOYDU, RINA, RUSSIAN MARITIME REGISTER SHIPPING, TÜV CERT, TÜV SÜD, GOST, TÜV AUSTRIA. The safety and durability of the products are ensured at the highest level.

- Material Selection: We use high-strength and corrosion-resistant steel materials in the production of our tanks. In this way, we provide long-lasting and safe use.

- Welding Processes: In welding processes, we meet the highest standards in terms of sealing and durability using the latest technologies.

- Testing and Control: Each tank is subjected to rigorous tests such as pressure tests and sealing controls. In this way, we offer reliable and quality products to our customers.

- Certification: Our production process is carried out in accordance with international standards and our tanks have the necessary certificates.

Yakut Kazan constantly renews itself and offers its customers reliable and efficient air tanks with the latest technology.

Sustainable Production

Quality Material

Fast Delivery

Certified Product

High Performance in Compressor Air Tanks

Yakut Boiler Compressor Air Tank offers flexible solutions to industrial needs with its customer-oriented production approach. Tanks optimized according to compressor capacity and air demand provide long-term benefits both economically and technically. Getting expert engineering support for the right air tank selection will guarantee system efficiency and safety.

Yakut Kazan, with its sustainable production vision, acts with the principle of “made-to-measure solution” in every project and maintains its leading position in the sector. Yakut Kazan designs and manufactures tanks optimized in terms of both storage volume and pressure resistance by examining the compressor specifications of its customers in detail.

Production Process of Yakut Kazan

Yakut Kazan manufactures air tanks in accordance with international standards.

- Engineering Calculations: Compressor capacity and air consumption data are used to determine tank volume mathematically.

- Material Selection: High quality steel is used to provide corrosion and pressure resistance.

- Testing and Quality Control: Maximum pressure resistance of tanks is guaranteed with Water, Pressure and Hydrostatic tests.

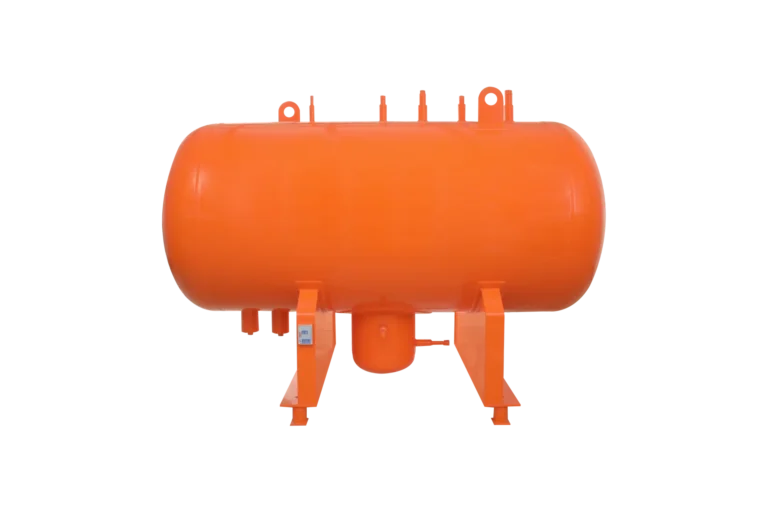

- Wide Range of Products: We offer a wide range of products with different capacities and pressure values. In this way, we can offer solutions suitable for the different needs of our customers.

- Customized Production: We can produce customized tanks according to the special demands of our customers.

- Technical Support: Our expert engineers provide technical support to our customers on tank selection, installation and maintenance.

- Optimum Design: We aim to maximize energy efficiency in the design of our tanks. In this way, we help our customers reduce their operating costs.

- Environmentally Friendly Production: We adopt a sustainable production approach by using environmentally friendly materials and technologies in our production process.

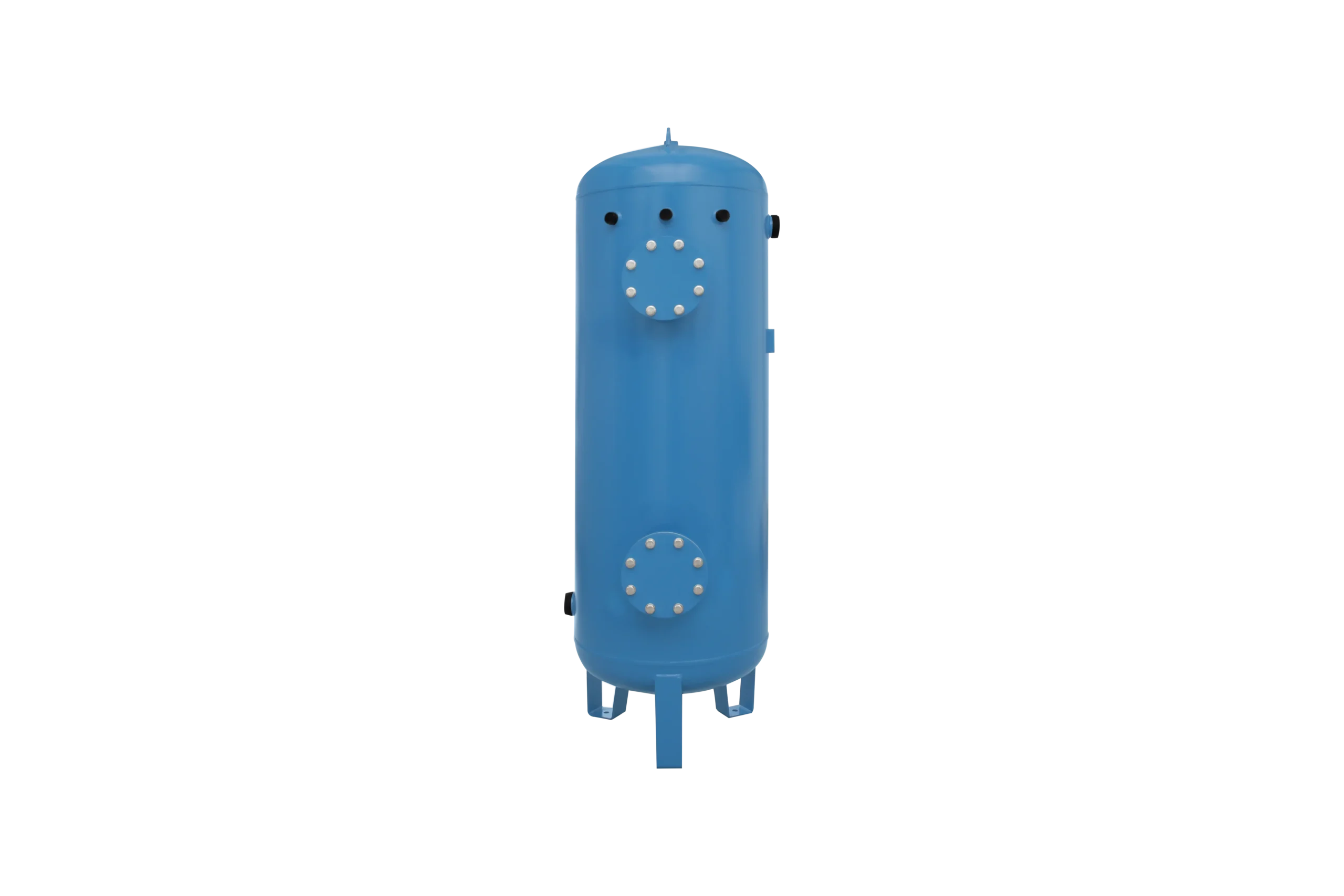

- High Durability: Electrostatic paint protects the tank surface against corrosion, scratches and other external factors, extending the life of the tank.

- Homogeneous Coating: This method ensures that an even and smooth paint layer is applied to the entire surface of the tank, thus achieving an aesthetic appearance and increasing the effectiveness of protection.

- Environmentally Friendly: Electrostatic painting produces less waste and harms the environment less than traditional painting methods.

- Long-Lasting Protection: Electrostatic paint provides long-term and reliable protection by ensuring that air tanks withstand harsh industrial conditions.

- Special Colors: Yakut Kazan uses RAL 5015 blue as standard, but also offers other standard color options according to customer needs.

- High Durability: Electrostatic paint protects the tank surface against corrosion, scratches and other external factors, extending the life of the tank.

- Homogeneous Coating: This method ensures that an even and smooth paint layer is applied to the entire surface of the tank, thus achieving an aesthetic appearance and increasing the effectiveness of protection.

- Environmentally Friendly: Electrostatic painting produces less waste and harms the environment less than traditional painting methods.

- Long-Lasting Protection: Electrostatic paint provides long-term and reliable protection by ensuring that air tanks withstand harsh industrial conditions.

- Special Colors: Yakut Kazan uses RAL 5015 blue as standard, but also offers other standard color options according to customer needs.

Certificates

Quality & Flawless

Industrial Solutions

Yakut Kazan is a pioneer in the sector with its specially designed and high quality tank manufacturing that adds value to the production processes of its customers.

PRODUCTS

The Choice of Successful Engineers Around the World Yakut Kazan

Our products are exported to GERMANY, ARNAVATIA, AUSTRALIA, AZERBAIJAN, UAE, BELGIUM, BOSNA HERSEK, BULGARIA, CZAY, CZECH, DENMARK, DOMINIC REPUBLIC, Ecuador, FAS, FRANCE, GABON, GANA, SOUTH AFRICA, GEORGIA, CROATIA, NETHERLANDS, IRAQ, UK, IRELAND, The products are exported to SPAIN, SWEDEN, ITALY, CANADA, QATAR, KENYA, KOREA, KOSOVA, LETONIA, HUNGARY, MACEDONIA, EGYPT, MOLDOVA, NEPAL, NORWAY, PERU, PORTUGAL, ROMANIA, SERBIA, SLOVAKIA, SLOVENIA, SAUDI ARABIA, TANZANIA, OMAN, GREECE.